PCM400 Series Portable Cleanliness Monitor

The Pall PCM400 is specifically developed as a portable diagnostic monitoring device that provides an assessment of system fluid cleanliness

Features

- Proven mesh blockage technology

- Results not affected by water or air

- Monitors dissolved water content (% saturation or PPM output for specific fluids (PCM400W only))

- High and low pressure on-line or off-line sampling

- Continuous monitoring

- 500 test memory

- ¼” BSP or test point hose connection

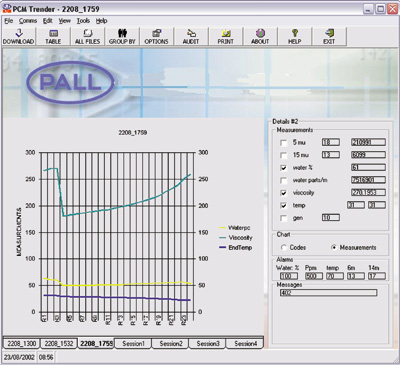

- PC-based trending software included

- Viscosity output in centistokes (cSt)

- Real time graphical representation

Benefits

As part of continued component cleanliness ‘pass off’ checks or predictive maintenance programs the PCM400 monitor quickly reports test data so that ongoing assessments can be made.

Early detection of abnormal fluid cleanliness allows for timely investigation and corrective actions to be implemented.

The PCM400 can be permanently installed to monitor critical applications (including component test facilities) or used as a portable device for routine condition monitoring of various fluid systems.