Mesh Blockage

Mesh Blockage

In 1984, Dr Trevor Hunt at Bath University patented the idea of determining the level of solid particulate in a fluid through the principle of pore obscuration in a mesh membrane.

This became known as the mesh blockage technique.

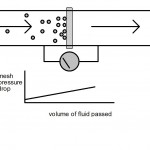

In essence, the process involves passing a fluid at a constant flow rate in a forward then reverse direction through a mesh membrane having a very precise pore size. Differential pressure (dp) is measured throughout the two cycles and any solid particulate larger than a mesh pore will become trapped, thereby reducing the effective open area of the mesh and increasing the differential pressure. By mathematical formula, the data is then converted into an assesed particle count and the corresponding cleanliness class.

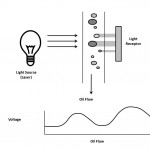

The advantages of mesh blockage over light blockage techniques include:

Not affected by aeration.

Not affected by free water.

Works well with multi-phase fluids.

Works well with very dark oils, including the monitoring of diesel engine oils

Works well even when large debris particles are present.

The mesh blockage technique is a very accurate, consistent and well proven method. More importantly, it has been developed and improved by IMS over the last twelve years.

In fact, the mesh blockage technique is now widely recognised for its success in both condition monitoring and roll-off cleanliness monitoring in flushing process. This has resulted in the recognition of the technique at ISO standard level – ISO 21018-3:2008 Hydraulic fluid power – Monitoring the level of particulate contamination of the fluid – Part 3 – use of the filter blockage technique.